Environmental Sealing Form in Place

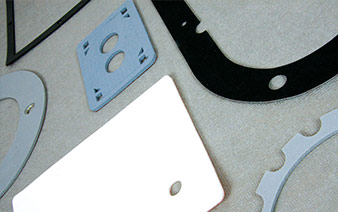

Kemtron Form-in-Place (FIP) Elastomer compounds are directly dispensed onto component hardware or enclosure via a pressurised fluid dispensing system on a numerically controlled XYZ table to form a gasket for dust and moisture sealing. The dispensing machine deposits the gasket by following a pre-determined CNC path to provide accuracy and repeatability.

Suited to applications where small, intricate gasket profiles are required, such as on multi-compartment labyrinth housings with minimum gasket land area where traditional larger types of gasket are not suitable. This process also negates the assembly costs associated with traditional gaskets as the Form-in-Place gasket becomes an integral part of the housing or enclosure. The process is suitable for depositing on both metal and metallised plastic components/housing.

Kemtron can dispense FIP gaskets directly onto the customer’s free issue hardware or can procure the component hardware thereby reducing the customer’s supply base. Kemtron can also supply FIP compounds in syringes or Semco cartridges for the customer’s own use.

- One-part RTV silicone rubber, many grades and colours to suit your application

- Electrically conductive RTV silicone for RFI/EMI shielding

Suited to applications where small, intricate gasket profiles are required, such as on multi-compartment labyrinth housings with minimum gasket land area where traditional larger types of gasket are not suitable. This process also negates the assembly costs associated with traditional gaskets as the Form-in-Place gasket becomes an integral part of the housing or enclosure. The process is suitable for depositing on both metal and metallised plastic components/housing.